5 Modern Technologies Every Manufacturing Business Should Look Out For

The manufacturing industry is one of the most profitable in the world. With a worth of over a trillion dollars, it’s easily one of the best industries for businesses to enter. And helping this ever-evolving and growing industry is technology.

Helping manufacturers to increase productivity, gain a vital competitive edge over others and reduce the need for human intervention, there is an exciting future for the industry.

But what are these innovative and exciting technologies that you should watch out for? Here are five that you should keep an eye out for if you’re running a manufacturing business looking towards future grow:

Virtual Reality

Similarly to many industries, virtual reality (VR) is taking many manufacturing businesses by storm. Simplifying product design from the get-go, it’s enabling engineers and designers to create realistic and effective product models that they can utilize to finalize a design before it goes into production.

For example, many automobile manufacturers are using the technology to design and test cars at the initial development stages. This helps to decrease time and cut costs – as well as ensure that the cars are safe for customers.

3D Printing

Many manufacturers are also starting to implement 3D printing within their operations. Not only does it help to make processes cheaper and quicker, but it allows designers to directly test and troubleshoot products before they go into the production stage.

Completed on-site within a short number of days, it takes the pressure off of your workforce and ensures that products are manufactured within a tight time frame.

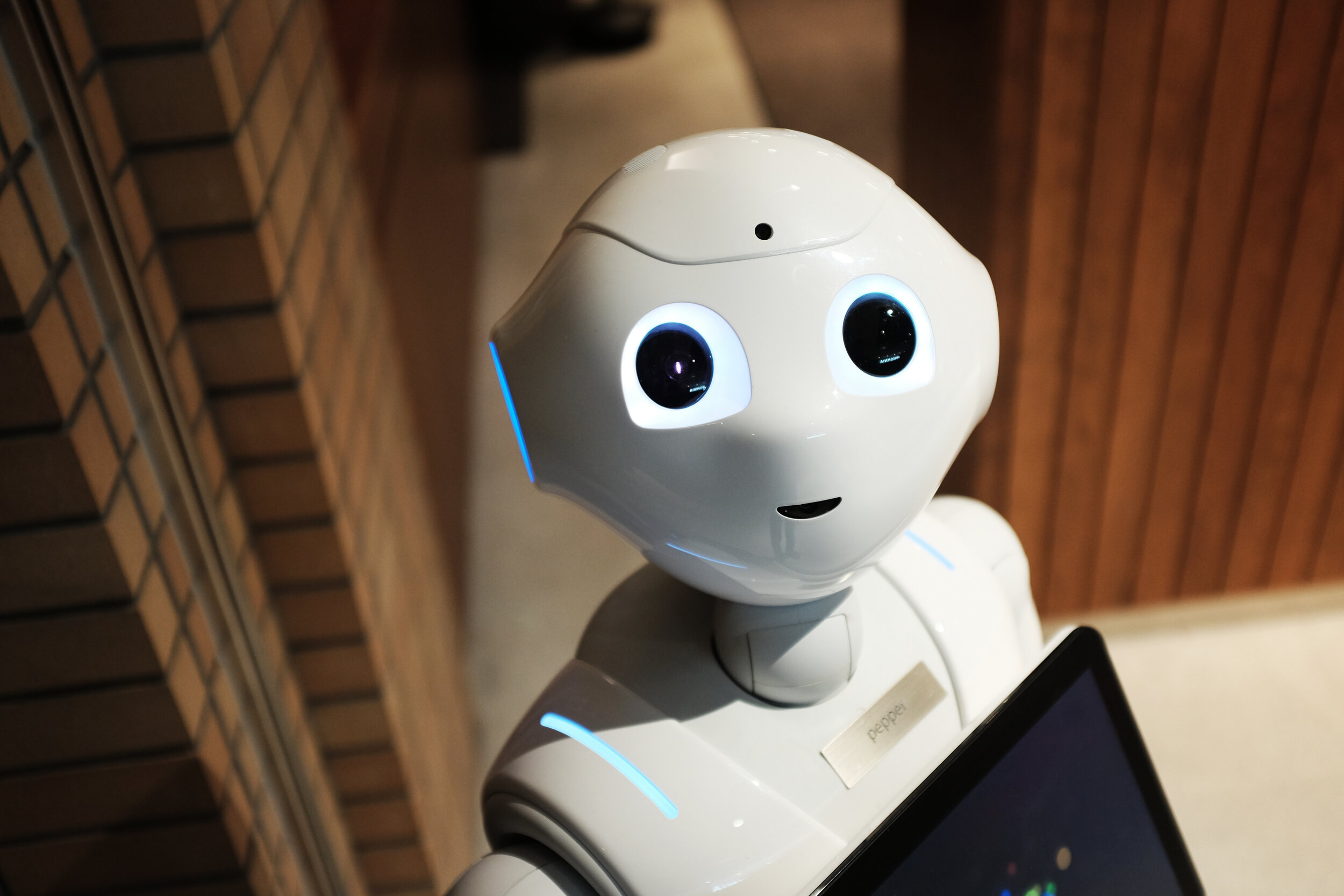

Collaborative Robots

Also fondly known as cobots, collaborative robots are designed to work alongside humans. With the potential to be worth billions of dollars in the next few years, collaborative robots are rapidly growing in demand. Helping on the assembly line, quality inspections, machine tending, etc. they are very effective for any manufacturing requirement.

Internet of Things

Although this technology has been around for a few years, the constant updates within it make it still prevalent within the manufacturing industry. Enabling manufacturers to connect various devices, it will ensure that all required compliance measures are met, processes are made more efficient, costs reduced and more innovative products.

Giving businesses access to real-time information, it allows for crucial decisions to be made quickly.

SMART Manufacturing

Another technology specifically designed to create an efficient workplace, SMART manufacturing involves machine learning and analytics. Vital to long-term success, it allows businesses to make future decisions that will benefit the company directly.

Final Thoughts

So, there you go! Those are the top 5 modern technologies that you should look out for within the manufacturing industry within the next few years. Of course, when looking at these, you need to keep in mind that technology alone won’t create a successful business.

You also need to establish goals for business growth, weigh up the pros and cons of each technology, source high-quality materials, work with reliable suppliers and set specific margins for your business.